Aggregate Bin

1.There is material shortage alarm device in each hopper, when the two fine aggregate material hopper is lack of material, it will alarm and vibrating automatically.

2.Cold aggregate supply motor adopts frequency conversion control,reliable; modularization design, easy to transport.It shows the China asphalt batching plant design.

Belt Conveyor

1.The driving & passive roller of the aggregate conveyor is equipped with pre-lubricated bearing,belt tension device and anti-slanting wheel; this could adjust the belt loose or tight.

2.Middle filter can prevent the waste material entering the dryer drum; reduce the heat loss. Avoid jam in the hot aggregate elevator and the vibrating screen.

3.The belt conveyor is also equipped with cleaning device to remove the small grain aggregate the stick on the belt, prevent the belt scratch and extend the service life.

2.Middle filter can prevent the waste material entering the dryer drum; reduce the heat loss. Avoid jam in the hot aggregate elevator and the vibrating screen.

3.The belt conveyor is also equipped with cleaning device to remove the small grain aggregate the stick on the belt, prevent the belt scratch and extend the service life.

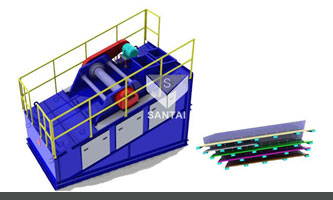

Drying Drum

1.Outside the drying drum is covered with a 50mm rock wool heat preservation layer,inside the drying drum fixing up diversified blades used for lifting aggregate, it whould be easy to exchange heat between the flame and the aggregate.

2.The drying drum is driven by four friction wheels, universal Joint, smoothly and evenly drive.

Vibrating Screen

4 layers mesh design, easy to replace and maintenance.A special design in China asphalt batching plant vibrating screen.

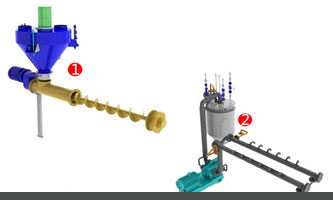

Weighing System

1.New and recycled filler could be weighed one by one. Weighing first then conveyor to increase accuracy, speed up and mixing evenly,meanwhile to reduce mixing time.

2.Asphalt weighing system adopts press compressive spray, to speed up and reduce mixing time, then increase production capacity.

Automation Control

1.Big motor adopt reasonable voltage-reducing starting.

2.Cold aggregate supply use frequency conversion control, adjust automatically.

3.Burner automatic ignition and control remotely.

4.Asphalt will be weighed by two steps and can inspect asphalt & aggregate ratio for each batch; Control is advanced, capability is credible, operation is convenient and obvious.

2.Cold aggregate supply use frequency conversion control, adjust automatically.

3.Burner automatic ignition and control remotely.

4.Asphalt will be weighed by two steps and can inspect asphalt & aggregate ratio for each batch; Control is advanced, capability is credible, operation is convenient and obvious.